Machine Learning-powered demand forecasting

What is capacity & demand forecasting?

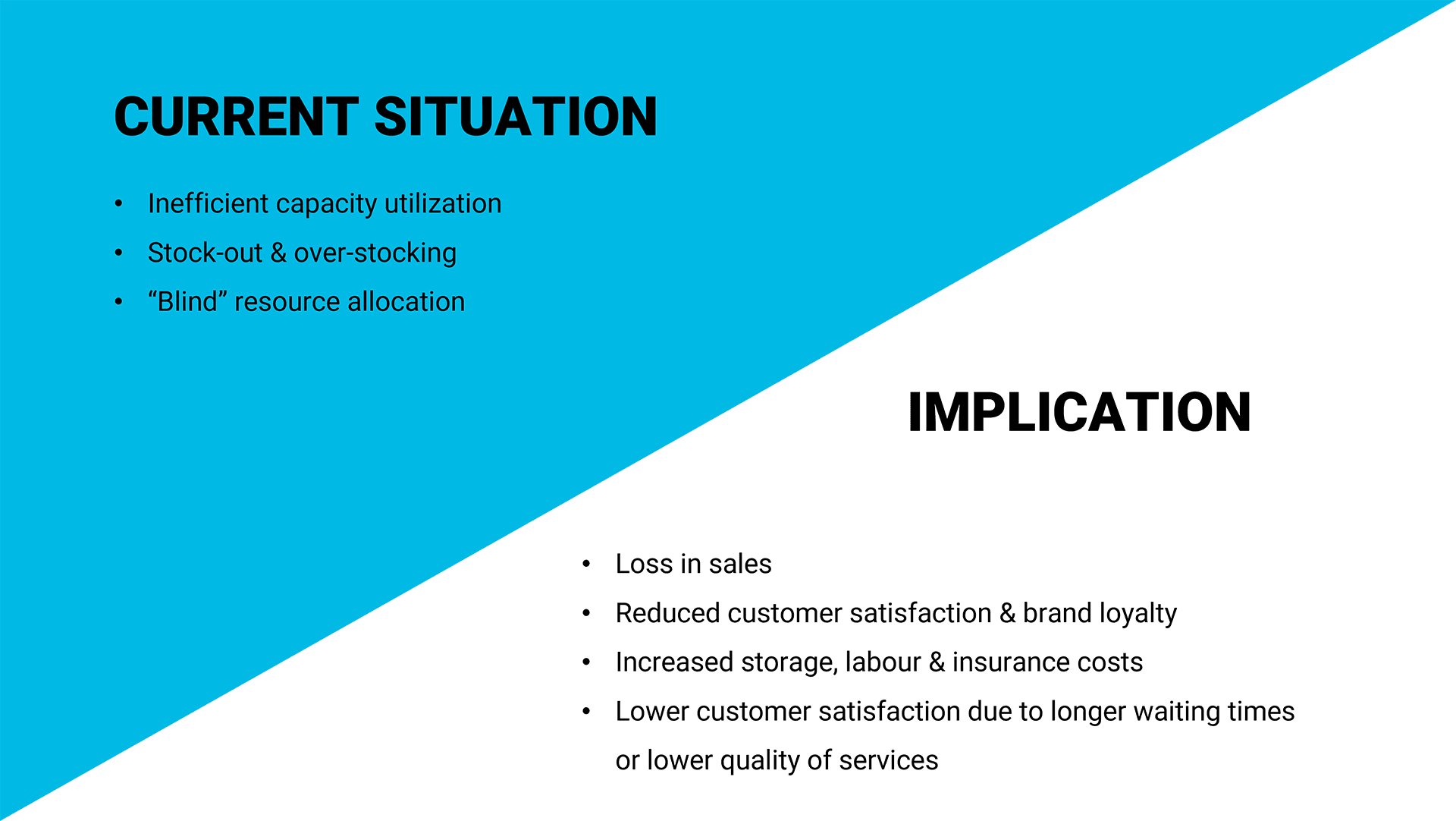

One of the biggest challenges for supply managers is handling demand volatility. Demand forecasting tries to estimate future orders or requests to pre-emptively detect resource and capacity shortages. Customer interactions and expectations are becoming increasingly complex due to more diverse and complex products and services entering the market. In most sectors, the task of accurate demand forecasting is hitting the boundaries of the human expert that uses his gut feeling to make estimates. We all know that person that uses their unique spreadsheet that only they know how to use. With customer purchase patterns becoming increasingly complex, those people spend more time making less accurate predictions.

To handle the increasing amount of data, business intelligence solutions are sometimes implemented to speed up the analysis. However, such solutions only slightly extend the inherently limited human capabilities to process the many variables in the process. It is important to acknowledge that BI tools do not tackle the main problem that there are just too many factors influencing demand to take into account manually, ranging from weather fluctuations to posts by social media influencers and external market conditions.

Luckily, the amount of internal and external data is growing to objectify and predict future demand in many sectors. AI models can process historical and current data to provide powerful forecasting algorithms.

How does machine learning revolutionize the method?

Machine learning-powered capacity planning helps you achieve the right balance of demand and supply in the chain. It enables enhanced forecasts based on real-time data using internal and external data sources such as demographics, weather, online reviews and social media. With the help of external data and modern machine learning algorithms, smart and semi-automated supply chain networks can outperform manually driven flows.

For new products that lack historical data, machine learning forecasting tools can identify clusters of prior products with similar characteristics and lifecycle curves and use those datasets as a substitute to make predictions. For your organisation, there’s no machine-learning expertise required. We develop modular blocks that are easy to interface with. You don’t have to develop complex models, get the training data and label the data yourself. Everything will be tailored-made to your needs and explained by our team.

Machine learning enables you to:

- Forecast capacity & demand (service or product)

- Ensure continuous product & resource availability

- Timely change or adjust processes

- Capture uncertainties

What are the benefits?

- Improving accuracy by time: Machine learning algorithms learn from existing data and make better predictions.

- Increased customer satisfaction: Stockouts reduce customer satisfaction while being available with your product anytime boosts customer satisfaction. Thus it improves brand perception and increases customer loyalty.

- Improved markdown/discount optimization: Cash-in-stock is a common situation for retail businesses. In this situation, certain products stay unsold longer than expected. This causes higher than expected inventory costs and increases the risk of these products going out of fashion or becoming obsolete, thereby losing their value. In these scenarios, organisations sell their products with reduced margins. With accurate demand forecasting, such scenarios can be minimized.

- Improved manpower planning: Demand forecasting for the entire year can support HR departments in making efficient trade-offs between the part/full-time employee mix, optimizing costs and HR effectiveness.

- Overall efficiency: Accurate demand forecasts help teams focus on strategic issues rather than firefighting to reduce/increase stocks and headcount to manage unexpected demand fluctuations.

Read more about the potential benefits according to this Mckinsey report.

How to adopt this technology

While demand planning and machine learning may go together as mayonnaise and fries (at least for our Belgian audience), successfully harnessing this technology requires careful consideration and preparation. Gartner research shows that “three of the top five reasons why organisations haven’t adopted AI are related to an inability to articulate a roadmap”. Luckily for you, we’ve already developed a roadmap with the most significant opportunities & pitfalls of implementing AI into your organisation.

ML2GROW can provide strategic advice on successfully embedding AI into your organisation. We have business strategists who have more than 10 years of experience in establishing and implementing digital transformation projects. They will establish your strategic AI roadmap in close collaboration using our best practices on digital strategy, data governance, and more.

With machine learning, reductions between 20 and 50% in forecasting errors are feasible. Lost sales due to products not being available can be reduced by up to 65% and inventory reductions of 20 to 50% are achievable.

Case: Brabo

The port of Antwerp is a world in itself. Very few outsiders know what happens in Europe’s second-largest port. Everyone knows the classic image of ships coming and going to load and unload goods. To make this possible, numerous players are needed, each of whom forms an indispensable link in the nautical chain in the port area: from lockmen, bridge keepers, tug crews and ship coordinators to pilots and boatmen. The safe piloting, mooring and unmooring of ships is the core business of Brabo.

Brabo provides training for port pilots and pilot services to control incoming and outgoing ships in the port of Antwerp. To cope with the increasing demand and always have sufficient capacity without unnecessary (high wage) costs, Brabo decided to invest in technology that predicts demand, enables better planning and avoids a capacity shortage given the associated high (private and social) costs.

ML2Grow successfully made a predictive machine learning system operational, enabling the port to react more quickly with their ship operations. Brabo’s pilot service window could be improved from 20 minutes to 8 hours thanks to these models, making a huge difference in Europe’s second-largest port.

Work performed

- Predictive machine learning models that capture planning uncertainties

Added value

- Captures the planning horizon for up to 8 hours

- Avoid expensive capacity shortages

- Reliable simulations of personnel assignments and alternative scenarios