Improve your manufacturing with computer vision

Computer vision focuses on creating digital systems that can process, analyse, and make sense of visual data (images or videos) in the same way that humans do. The concept of computer vision is based on teaching computers to process an image and understand it.

A machine vision system uses a camera to view an image, computer vision algorithms then process and interpret the image, before instructing other components in the system to act upon that data. Computer vision can be used alone, without needing to be part of a larger machine system.

Computer vision applications are used across industries to improve the consumer experience, reduce costs, and tighten security. Manufacturers use it to spot defective products on the assembly line and prevent them from shipping to customers. Insurance adjusters use it to assess vehicle damage and reduce fraud in the claims process. Medical professionals use it to scan X-rays, MRIs, and ultrasounds to detect health problems. Banks use it to verify customers’ identities before conducting large transactions.

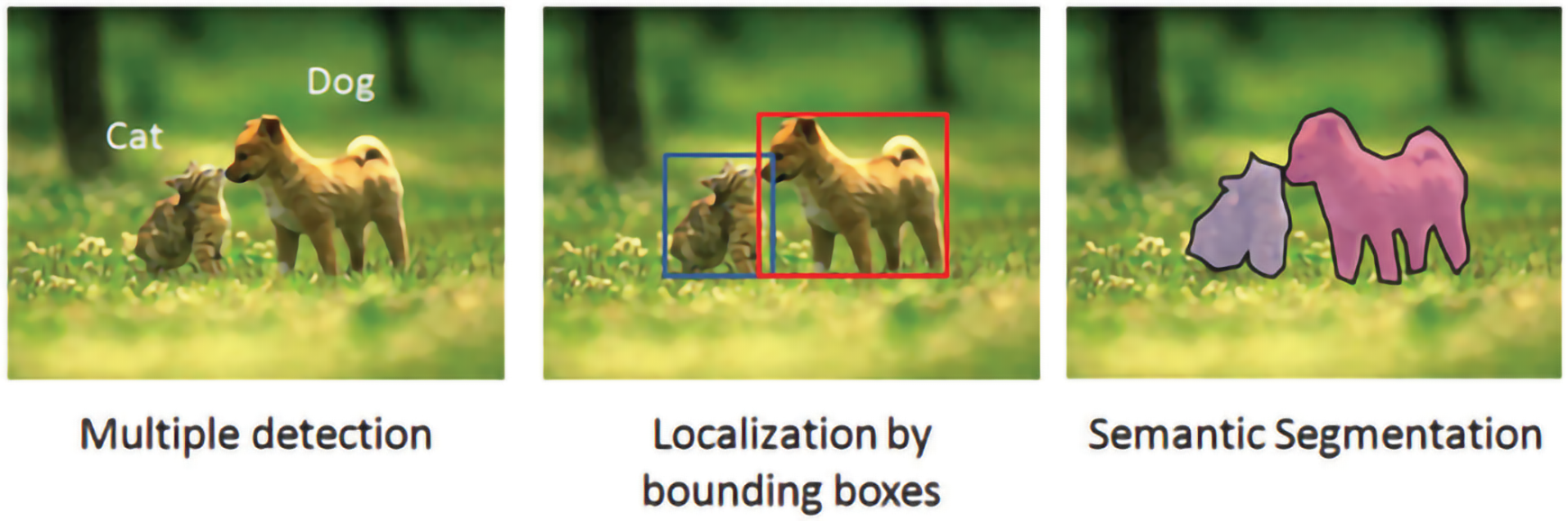

Different types of computer vision include image segmentation, object detection, facial recognition, edge detection, pattern detection, image classification, and feature matching.

Quality inspection

Visual quality control is most of the time still happening by means of a control table controlled by an operator, manually detecting errors in specific areas (manufactured goods, high-value assets like vehicles, windmills, pipelines, …) .

There is a shift happening by a lot of manufacturers striving towards fully automated production to boost the efficiency and speed of quality inspection. To stay competitive, fewer faults and zero margins for errors combined with an ever-increasing demand require further (intelligent) automation, the adoption of this technology would allow them to further improve their production process.

Image acquisition – the action of retrieving an image from a source, usually hardware systems like cameras, sensors, etc. It is the first and the most important step in the workflow sequence because, without an image, no actual processing is possible by the system.

There are two types of camera inspection being used for an inspection today: area scan and line scan. Area scan camera systems inspect one area in each picture. Taking and processing a new picture takes 1-2 seconds. Line scan camera systems inspect 100 per cent of the material, 100 per cent of the time by inspecting across the web in one long line, at rates of 14,000 lines per second.

Defect detection & image repository

Every defect type that must be identified requires initial training of the computer vision model to ensure that the model classifies the defect into the correct type.

The model is trained by providing it images of the desired defect (‘labelled images’) when the model is offline – we call this a ‘Training set’. A model that been trained or re-trained must always be validated before going to production as we don’t know the impact on the overall accuracy of the model. Therefore every ‘Training set’ must be split into a set of images used to (re-)train the model and a set of images that are untouched, called the ‘test set’. The latter set is used to evaluate the performance and estimate the generalization potential of the model towards unseen data. Tuning the model typically occurs on a third partition: the validation set.

- 1. Optical illumination

The main function of an optical illumination platform is to overcome the interference of environmental lighting, ensure the stability of the image, and obtain an image with a high contrast. Thus, the main goal of the optical illumination platform is to make the important features of the objects visible and reduce undesired features of the objects.

A targeted optical illumination system must be designed according to the specific needs of the project, characteristics and motion state of the coating line, its surrounding environment and the type of camera. Important is to analyse the difference between the target and the background to find out the difference in the optical phenomenon between them (i.e. making the contrast as high as possible).

- 2. AI model

The final but continuous phase of ML development is model monitoring and maintenance. As with any piece of machinery, an AI model requires regular tuning and updating to meet performance expectations (e.g. adding more defects in the future, changes with totally different canvases, …- any external change could affect the model positively or negatively ). Failing to perform this essential step may result in diminishing model accuracy over time.

In addition, an ML module is a special type of software that is being integrated into the total production system. This requires a good set of best practices to ensure a robust system (MLOps).

The automated quality control process that we implemented for our customers now safeguards their brand reputation by minimizing faults in production lines and allows the operators to focus on more meaningful tasks and less repetitive work

Benefits

- Industrial machine vision works with the cycle rate of the production plant, allowing for 100% machine utilisation. Production downtime is minimised in this way.

- 100% quality control. Guaranteed quality is a decisive buying and pricing point for your customers.

- The best workload for human resources. Your production gets more efficient and therefore more economical.

- Flexible systems allow for very fast conversion of production. Changeover times are minimised.

- Your delivery reliability increases. Downtime at your customers is prevented in this way.

- Free up FTE and assign them to new tasks and roles inside the company that is beneficial for all parties

Monitoring

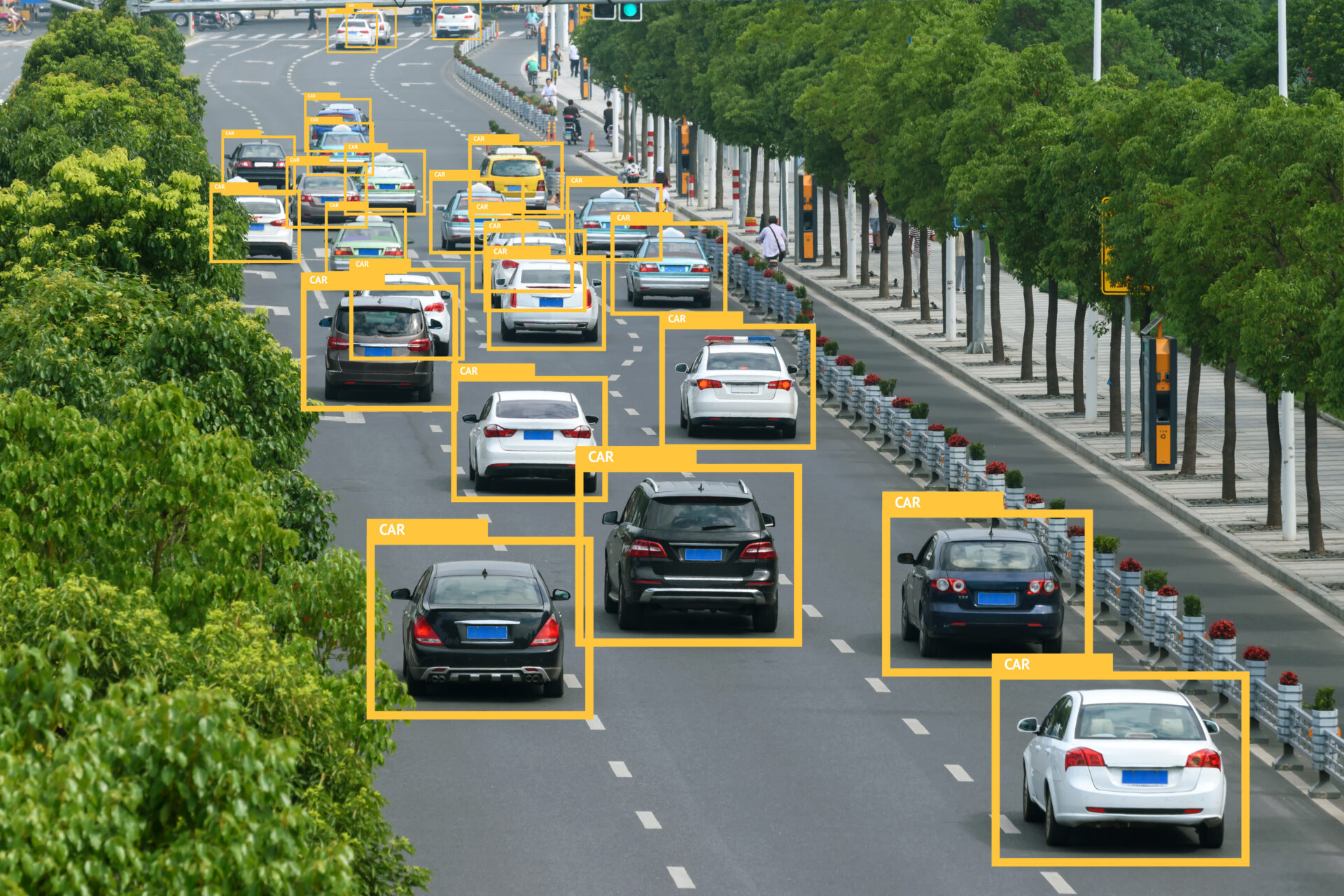

Monitoring is another use case of computer vision and is done by object identification.

It can detect, recognize, count and track objects of interest within video data. The approaches developed are capable of responding to specific tasks in terms of continuous monitoring and surveillance in many different application frameworks: improved management of logistics in storage warehouses, counting of people during event gatherings, monitoring of subway stations, coastal areas, etc.

This differs from the classification task by applying classification and localization to many objects instead of a single dominant thing. Object identification has many use cases with a tremendous impact on different industries. For example, real-time object detection can be used in a manufacturing plant. Security cameras can detect if workers are wearing their hard hats, gloves and other safety requirements. Or in agriculture, object detection models can accurately recognize and find the potential instances of plant diseases.

Tracking & flow analysis

With tracking & flow analysis, we can learn systems to process video to find objects (or objects) that match search criteria and track their movement. In other words, object tracking is the task of automatically identifying objects in a video and interpreting them as a set of trajectories with high accuracy.

You may know it from object tracking in automated cars such as tesla. There’s an indication around the object being tracked, mostly a surrounding square that follows the object, showing the user where the object is on the screen.

Our method

Our main goal is to take control of the project and fully unburden the customer for achieving the set goals. We will assess and install the preferable camera and roll out our AI solution to process the visual data. We create private secured data storage and a cloud system for storing the data and develop a feedback system for the operator. Our job is also to train the employees with the new technology and use their feedback to perfect the design.